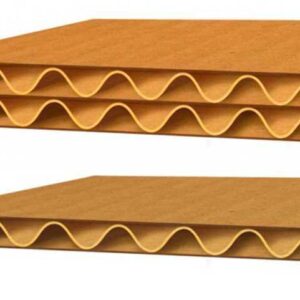

Cardboard is excellent for project construction because it is easy to cut, bend, fold, and drill, yet has quite a high strength to weight ratio. This strength is due to the stable arches inherent in the fluted corrugated inner wall.

Price index: the higher the index the lower the price

Cardboard is excellent for project construction because it is easy to cut, bend, fold, and drill, yet has quite a high strength to weight ratio. This strength is due to the stable arches inherent in the fluted corrugated inner wall.

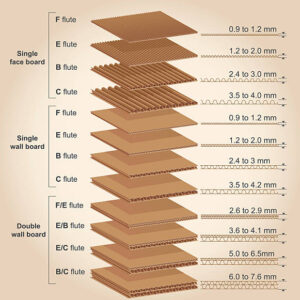

Effectively, a standard sheet of cardboard is made from 3 components. These are a sheet of corrugated or “fluted” material in the centre, placed between 2 layers of paper – the outer and inner liners.

Each side of the fluted material is glued to the flat paper liner during manufacture. The glue fixes the flutes in position and adds rigidity and stability to the papers.

There are a number of different thicknesses of corrugated fiberboard made. The most common are designated by the fluting letters ‚A‘, ‚B‘, ‚C‘, ‚D‘, ‚E‘, and ‚F‘. The most common, used in most typical shipping boxes, is ‚A‘ flute, which is 3/16″ (4.8mm) thick.

Specifications

THIS CARD IS BEING PREPARED

Material Health

Material Health

Material Reusability

Material Reusability

Water Consumption

Water Consumption

Social Responsibility

Social Responsibility

Global Availability

Global Availability

Price/Value

Price/Value

Retail Monkeys Index

Retail Monkeys Index

#paper #PVCfree #FSC #recyclable #sheet #doublesided #indoor